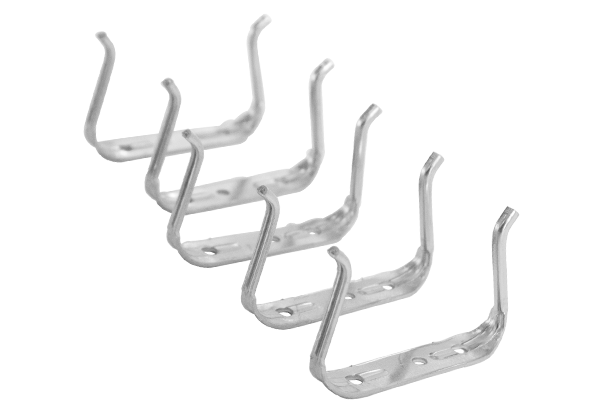

CONTACT FOR CAR HORN WITH TORCH

Industry: Automotive

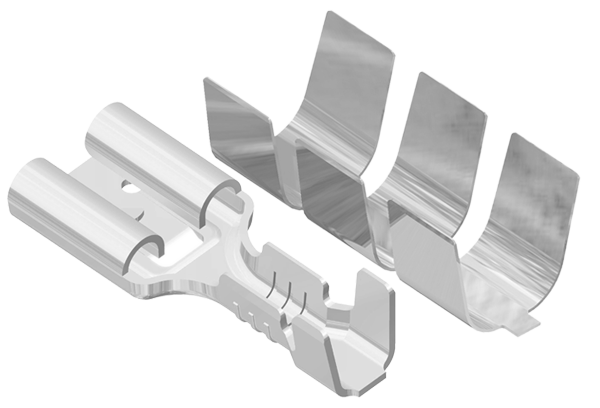

Customer need: European producer of batteries and car horns needs to develop a new metal terminal for a horn, with the dual function of obtaining the passage of current and at the same time having a resilient contact so that it can withstand the stresses and without deformation of the connection unit.

GMG proposed solution: the solution according to GMG, to ensure the difficult combination of stability in the connection and flexibility of the contact, is to invest time and energy in creating longitudinal slits spaced equally along the axis of the deep drawn part, so that the release of the terminal is prevented in the use phase even under conditions of mechanical stress. The balance was definitively obtained by precisely processing the material in areas adjacent to the contact and intelligently using its spring back field.

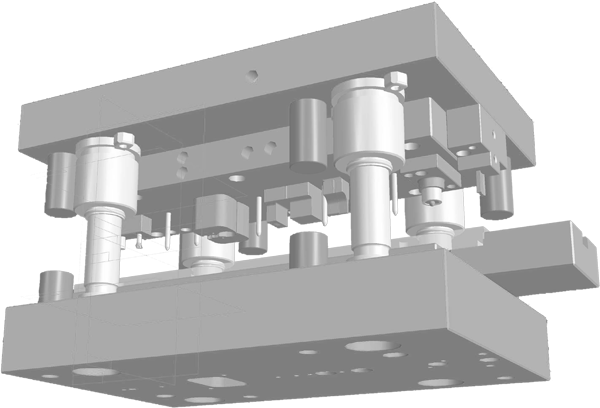

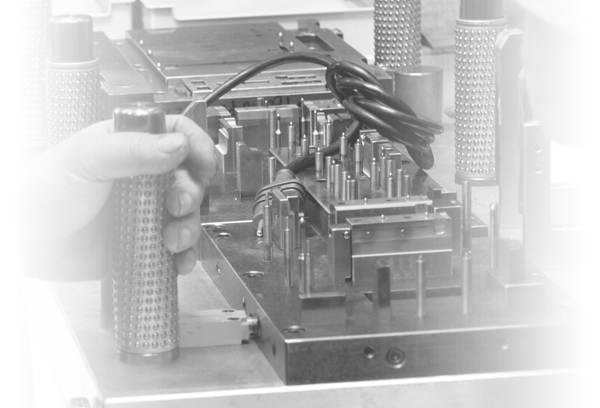

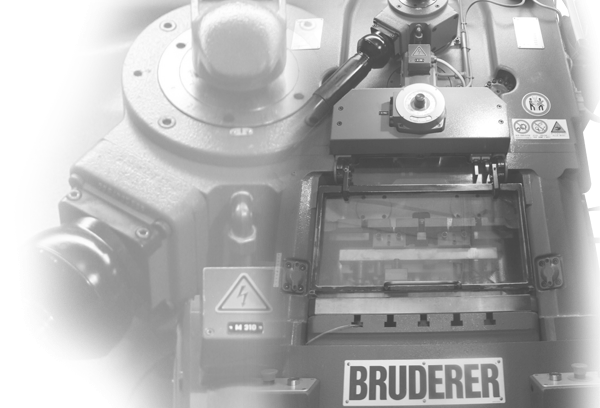

How to obtain the result: in the study phase of the progression mould, the GMG technical team has provided a logical sequence of steps in which the component could be reinforced at the base of the deep drawn part, shortly before the creation of the longitudinal slits, so as to ensure the obtaining of technical and quality specifications expected by the customer.