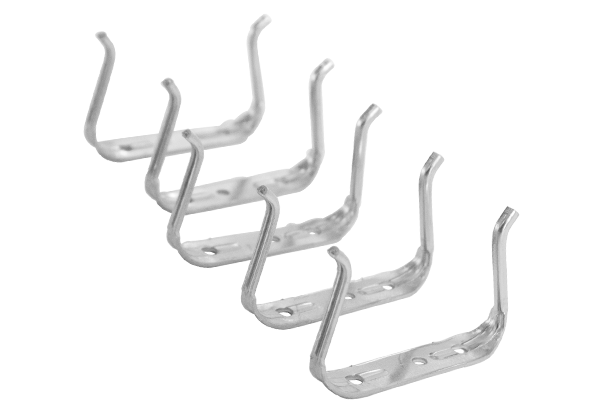

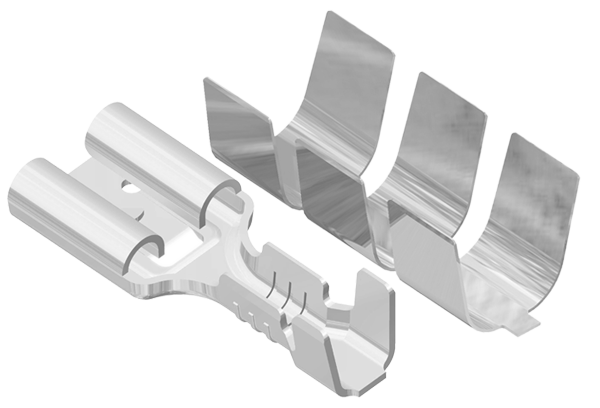

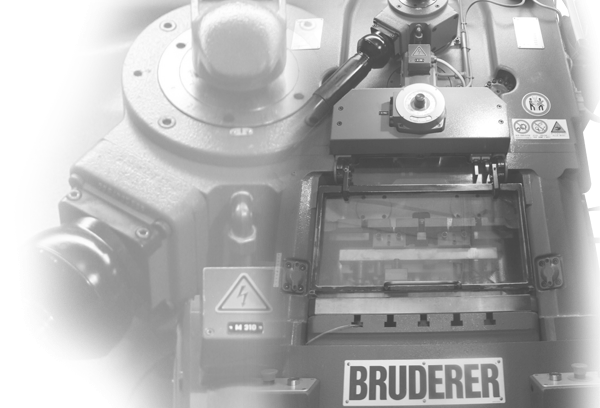

Stamping by shearing and bending

This processing can be performed on strips or bands of sheet metal, in particular for operations such as:

- shearing

- bending

- coining

- drawing

made by using as a sheet raw material wrapped in a strip or in a band with thicknesses from 0.1 mm to 4 mm.

The strips can be:

- Low carbon steel

- stainless steel

- bimetal strips

- brass, raw and pre-processed

- bronze- copper

- aluminium

- nickel

- beryllium copper

- pre-processed materials

- silicon iron

- electrogalvanised, pre-painted or pre-tinned steel

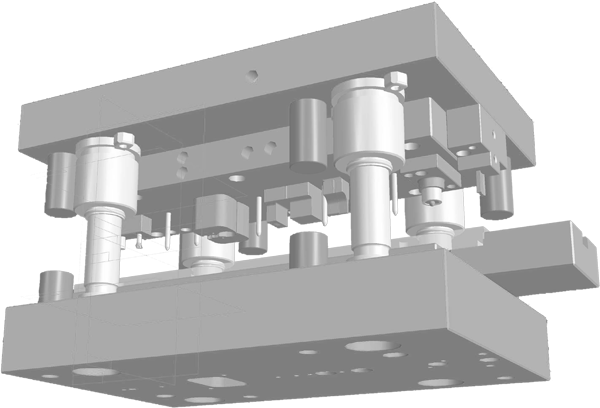

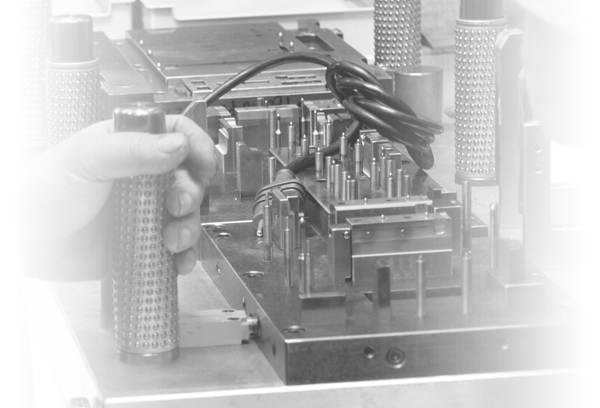

For moulds for high standard production, steels are used that are made through powder metallurgy and subsequently subjected to PVD surface treatments, with the aim of significantly increasing the wear resistance in the shearing operations.

For special solutions in sheet metal stamping, hard metal punches and dies are used.

For moulds for small productions, devices are used, such as modules and integrated sub-assemblies, special equipment for rapid prototyping, with the aim of rationalizing costs and providing very high product quality to the customer.

- bending

- coining

- drawing

made by using as a sheet raw material wrapped in a strip or in a band with thicknesses from 0.1 mm to 4 mm.

The strips can be:

- Low carbon steel

- stainless steel

- bimetal strips

- brass, raw and pre-processed

- bronze- copper

- aluminium

- nickel

- beryllium copper

- pre-processed materials

- silicon iron

- electrogalvanised, pre-painted or pre-tinned steel

For moulds for high standard production, steels are used that are made through powder metallurgy and subsequently subjected to PVD surface treatments, with the aim of significantly increasing the wear resistance in the shearing operations.

For special solutions in sheet metal stamping, hard metal punches and dies are used.

For moulds for small productions, devices are used, such as modules and integrated sub-assemblies, special equipment for rapid prototyping, with the aim of rationalizing costs and providing very high product quality to the customer.