Project Development

One of the characteristics that set GMG apart is the utmost focus that the project team gives to the following project development stages:

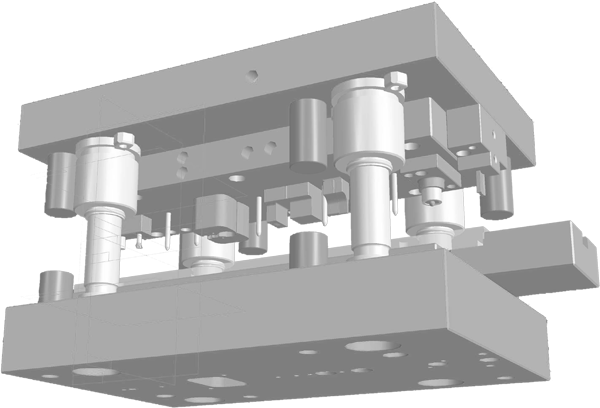

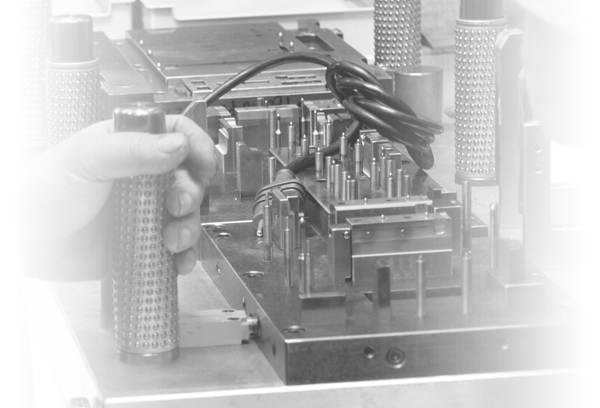

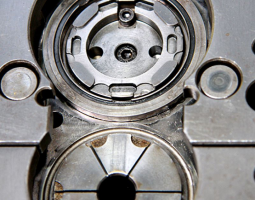

DESIGN FOR PRODUCTION

The idea of design for manufacturing and assembly is important to our company. We pay close attention to the standardisation of the components of our moulds, to the reuse of parts developed in the past and the simplification of the product resulting from a bottom-up approach. We always pay great attention to the definition of production families for the containment of product varieties, modular architecture definition, ease of mould assembly, to be more reactive in production.

We carry out training and support activities for our staff on the use of certain tools and methodologies resulting from the need for simplification.

INVOLVEMENT OF PRODUCTION IN DESIGN

The production is involved in design at an early stage and helps to identify the functional product solutions.

This allows us to reduce costly design changes that require additional hours of design, greatly extending the development time.

INTEGRATION WITH SUPPLIERS

We have put policies in place to reduce and select the supplier base in order to initiate more collaborative and long-term relationships.

From the initial stages of the development process we involve the suppliers/sub-suppliers who have more weight in the project and we greatly value their suggestions and considerations. This greatly increases our ability to contain the problems of quality, production costs and to shorten the response time to the market.

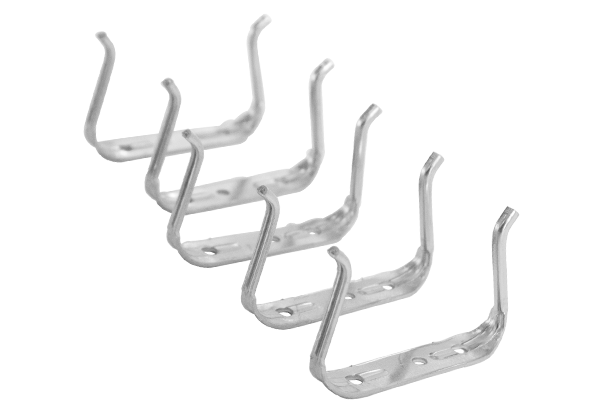

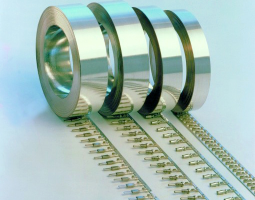

STRONG PRODUCT DESIGN

We design robust products with respect to the variability of the raw materials/components and production processes. This allows us to optimise the use of materials and reduce costs.

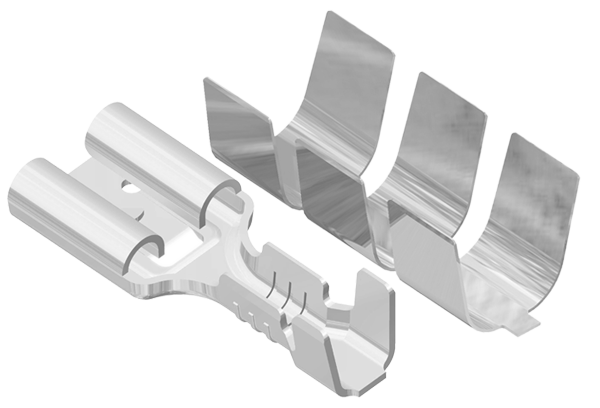

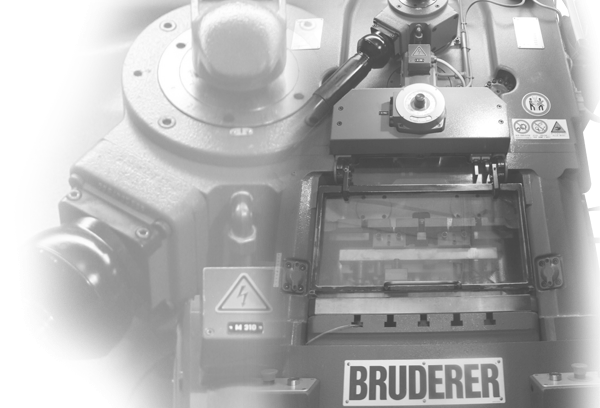

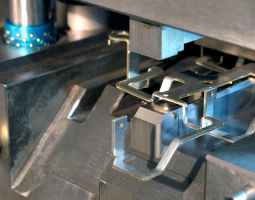

LAUNCH IN PRODUCTION

The tests performed on prototypes and pre-series products can reduce, in the launch of the initial production, the problems related to the use of equipment, tools and processing. This allows us to reliably calculate the unit needs and the total of the materials and capacity and, ultimately, to make a quick start to full production.

The idea of design for manufacturing and assembly is important to our company. We pay close attention to the standardisation of the components of our moulds, to the reuse of parts developed in the past and the simplification of the product resulting from a bottom-up approach. We always pay great attention to the definition of production families for the containment of product varieties, modular architecture definition, ease of mould assembly, to be more reactive in production.

We carry out training and support activities for our staff on the use of certain tools and methodologies resulting from the need for simplification.

INVOLVEMENT OF PRODUCTION IN DESIGN

The production is involved in design at an early stage and helps to identify the functional product solutions.

This allows us to reduce costly design changes that require additional hours of design, greatly extending the development time.

INTEGRATION WITH SUPPLIERS

We have put policies in place to reduce and select the supplier base in order to initiate more collaborative and long-term relationships.

From the initial stages of the development process we involve the suppliers/sub-suppliers who have more weight in the project and we greatly value their suggestions and considerations. This greatly increases our ability to contain the problems of quality, production costs and to shorten the response time to the market.

STRONG PRODUCT DESIGN

We design robust products with respect to the variability of the raw materials/components and production processes. This allows us to optimise the use of materials and reduce costs.

LAUNCH IN PRODUCTION

The tests performed on prototypes and pre-series products can reduce, in the launch of the initial production, the problems related to the use of equipment, tools and processing. This allows us to reliably calculate the unit needs and the total of the materials and capacity and, ultimately, to make a quick start to full production.