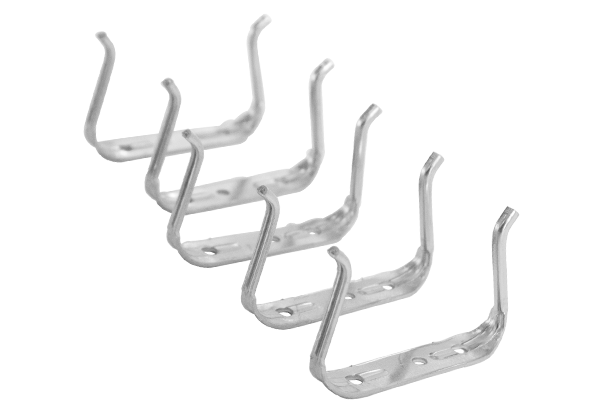

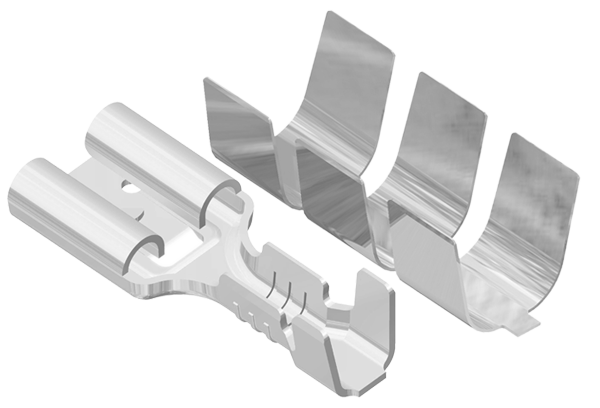

Ring terminals

If you are looking for ring terminals, G.M.G. is a leading company with more than 40 years’ experience.

The synergy between innovation and experience has allowed GMG to become the most important partner for great companies all over the world, which appreciate its precision, speed and production capacity. In particular, GMG can produce up to ten million small metal parts of any size every day.

Compliance with the most stringent international standards, such as UNI EN ISO 9001:2008, ensures safety and quality to the customer. The implementation of the just-in-time strategy has optimized costs and sped up the time-to-order, i.e. the delay between ordering and delivery a product.

The customer can choose among many kinds of small metal parts: with galvanic coating, brass, various alloys and copper – included beryllium copper (BeCu) –.

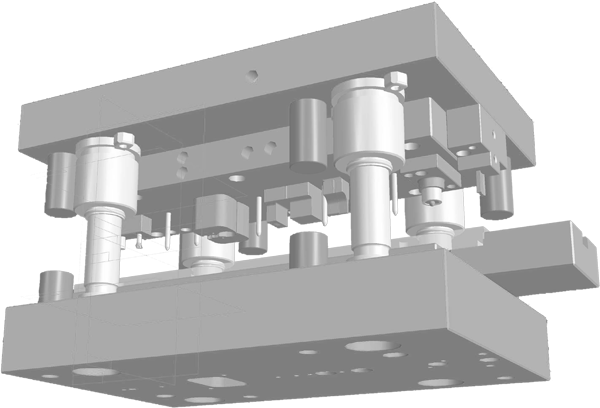

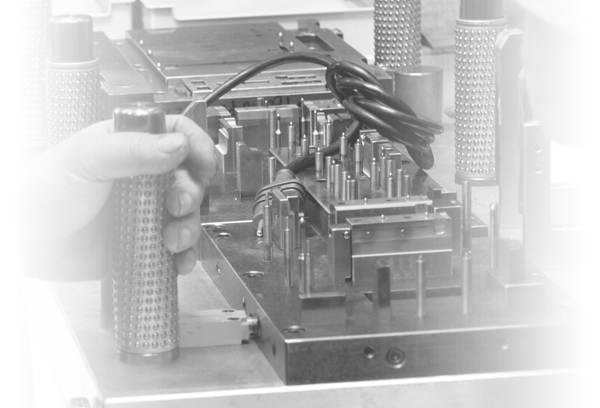

CAD-CAM systems ensure speed and accuracy both in the design and in the production phase. GMG experts create a prototype, i.e. a 3D sample leading to the final ring terminal.

Prototyping techniques identify potential flaws, thus helping to improve the product before starting the manufacturing phase.

Our sales department will be happy to provide you with further information and a free quote about ring terminals.

Request for information

Related Pages

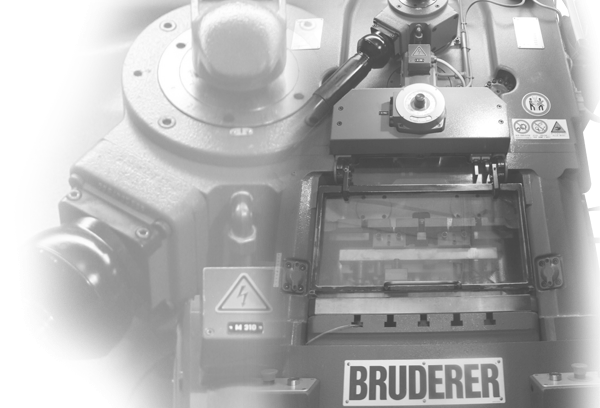

High speed stamping of terminals and connectors

An efficient and technologically advanced production system that allows the prod...

Stamping for deep drawing

The drawing processing of the sheet metal consist of plastic deformation operati...