Technology

OUR TECHNOLOGY IS INCREASINGLY REFINED

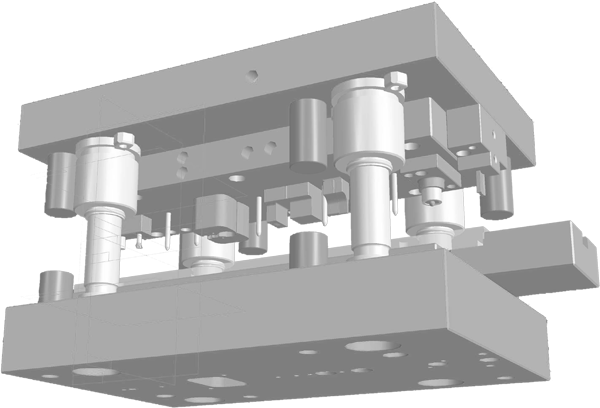

The projects are developed and executed with CAD-CAM systems.

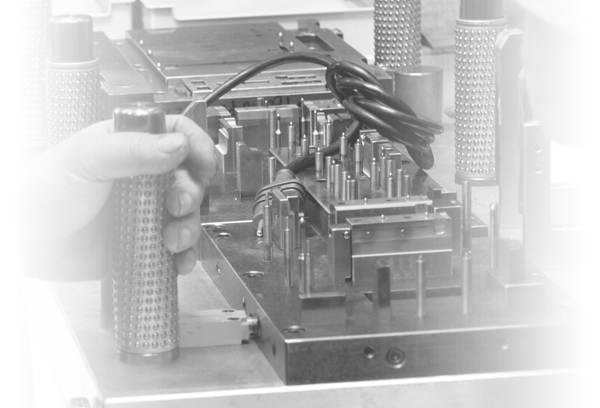

The equipment and moulds are constructed internally by our technical staff who take care of every detail, even the start-up of the prototypes, thanks to more than thirty years’ experience that allows us to satisfy all expectations in an increasingly competitive market.

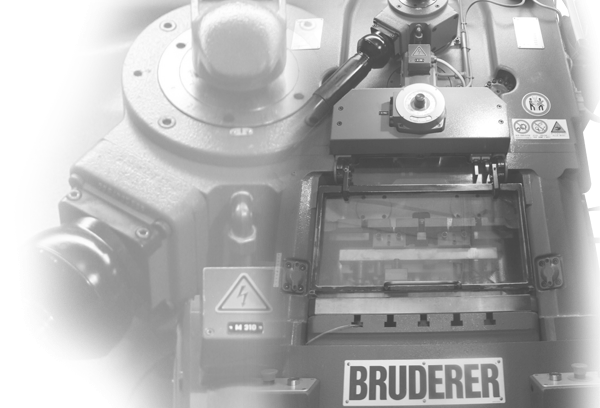

The diverse range of presses allows us a stamping power which varies from 25 to 250 tonnes with stamping speed up to 1400 strokes/minute.

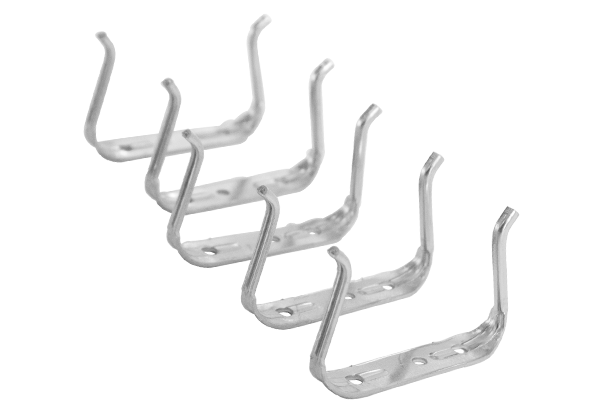

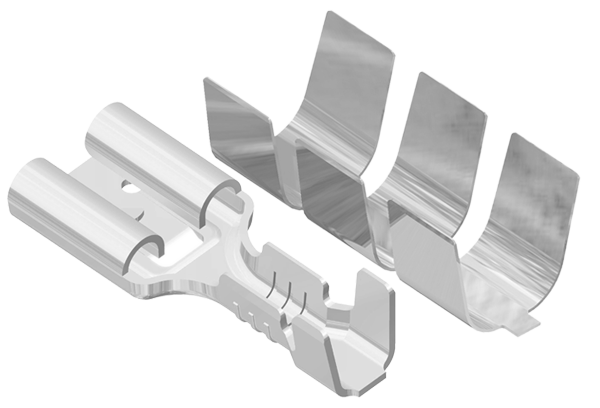

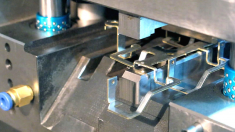

We mould with cold bending drawing and slicing techniques using progressive step moulds.

The processed raw materials, in the form of laminated strips, have a thickness that ranges from 0.1 to 3.5 mm as needed.

Machines, products and appropriate cleaning cycles allow us to obtain clean parts in compliance with applicable environmental laws.

Process control techniques allow us to obtain reliable production and problem solving techniques, allowing us to continually improve our performance.

In fact, we create thousands of products whose features are accuracy, precision and reliability.

Large and small sizes

Productive technologies and means for the realisation of an average daily volume of more than 10 million pieces, with high yields and with JUST IN TIME delivery philosophy

Materials and Finish

Copper, brass, nickel, beryllium copper, Tombacco, phosphor bronze, technical alloys resistant to high temperatures, stainless steels, iron, pre-treated materials, heat treatments, galvanizing coatings

Complexity

Complex shapes obtained with the technology of the moulds in step with material thicknesses up to 3 mm

Precision

Reference Standards, Measurement Instruments, Process Control, CP - CPK - PPAP. Everything for obtaining industrial productions according to the agreed quality and dimensional standards

The equipment and moulds are constructed internally by our technical staff who take care of every detail, even the start-up of the prototypes, thanks to more than thirty years’ experience that allows us to satisfy all expectations in an increasingly competitive market.

The diverse range of presses allows us a stamping power which varies from 25 to 250 tonnes with stamping speed up to 1400 strokes/minute.

We mould with cold bending drawing and slicing techniques using progressive step moulds.

The processed raw materials, in the form of laminated strips, have a thickness that ranges from 0.1 to 3.5 mm as needed.

Machines, products and appropriate cleaning cycles allow us to obtain clean parts in compliance with applicable environmental laws.

Process control techniques allow us to obtain reliable production and problem solving techniques, allowing us to continually improve our performance.

In fact, we create thousands of products whose features are accuracy, precision and reliability.

Large and small sizes

Productive technologies and means for the realisation of an average daily volume of more than 10 million pieces, with high yields and with JUST IN TIME delivery philosophy

Materials and Finish

Copper, brass, nickel, beryllium copper, Tombacco, phosphor bronze, technical alloys resistant to high temperatures, stainless steels, iron, pre-treated materials, heat treatments, galvanizing coatings

Complexity

Complex shapes obtained with the technology of the moulds in step with material thicknesses up to 3 mm

Precision

Reference Standards, Measurement Instruments, Process Control, CP - CPK - PPAP. Everything for obtaining industrial productions according to the agreed quality and dimensional standards

Variable strokes

The distance over which the moulds must work to produce the component and ensure the free space to remove it determines the stroke length.